Unit Overview:

Diverters by DMN-WESTINGHOUSE come in many types and sizes, suitable for a specific use or a variety of applications. The extensive diverter range comprises a series of plug diverters (dual pipe, single pipe, CIP suitable, gravity) and tube diverters (2-14 ports), some of which are also available in USDA Dairy accepted version. For the mineral industry, the BTD ball type diverter with its rugged design is very suitable for handling abrasive products.

DUAL PIPE PLUG DIVERTER - PTD-II

SINGLE PIPE PLUG DIVERTER - SPTD

SINGLE PIPE PLUG DIVERTER - SPTDS

TUBE DIVERTER - 2-TDV

TUBE DIVERTER - 3-TDV

MULTI-PORT TUBE DIVERTER VALVE - M-TDV

BALL TYPE DIVERTER - BTD

The DMN-WESTINGHOUSE PTD plug type diverters have been specially designed to route powders and pellets with minimum degradation in pneumatic conveying systems. The PTD plug type diverter is applied in the chemical, pharmaceutical, plastic, food and other related industries. A smooth passage of products is guaranteed by precision machining, a good sealing and a complete obstruction free passage. The user friendly fool proof design enables fast in situ internal examination, cleaning and, if necessary, replacement of seals. The PTD design conforms to all current legislation regarding safety in the workplace. Consequently there are no moving parts on the outside. The PTD is available in 7 different pipe sizes: ∅ 50, 65, 80, 100, 125, 150 and 200 mm.

The SPTD single straight pipe plug diverter has been specially designed to route powders and pellets with minimum degradation in pneumatic conveying systems. The straight pipe makes the SPTD very suitable for applications in the food, pet food, plastics (recycling) and petrochemical industries. A smooth passage of product is guaranteed by precision machining, very effective sealing and a complete obstruction free passage. The user friendly fool proof design enables fast in situ internal examination, cleaning and, if necessary, replacement of seals. The design of the SPTD plug diverter conforms to all current legislation regarding safety in the workplace. Consequently there are no moving parts on the outside. The SPTD is available in 6 consecutive sizes from 150 up to 400. For smaller sizes we offer the SPTDS single straight pipe plug diverter, which is available in 5 consecutive sizes from 50 up to 125.

The SPTDS single straight pipe plug diverter has been specially designed to route powders and pellets with minimum degradation in pneumatic conveying systems. The straight pipe makes the SPTDS very suitable for applications in the food, pet food, plastics (recycling) and petrochemical industries. A smooth passage of product is guaranteed by precision machining, very effective sealing and a complete obstruction free passage. The user friendly fool proof design enables fast in situ internal examination, cleaning and, if necessary, replacement of seals. The design of the SPTDS plug diverter conforms to all current legislation regarding safety in the workplace. Consequently there are no moving parts on the outside. The SPTDS is available in 5 consecutive sizes from 50 up to 125. For larger sizes we offer the SPTD single straight pipe plug diverter, which is available in 6 consecutive sizes from 150 up to 400.

The 2-TDV and 3-TDV transport pneumatically conveyed products in powder or pellet form to or from two respectively 3 destinations (diverging or converging). The 2-TDV and 3-TDV are compactly designed and by using an additional line cylinder on the 3-TDV very accurate positioning is achieved. The diverters are designed to be easily removed from the line for cleaning (COP – cleaning out of place). It is also possible to purge the individual conveying lines with a cleaning liquid without removing the diverter from the line (CIP – cleaning in place). Removal from the line is only necessary when a complete cleaning operation is required. This gives the customer the option to chose a cleaning method tailored to suit their process. The 2/3-TDV and M-TDV tube diverter range includes USDA Dairy Accepted models.

The 2-TDV and 3-TDV transport pneumatically conveyed products in powder or pellet form to or from two respectively 3 destinations (diverging or converging). The 2-TDV and 3-TDV are compactly designed and by using an additional line cylinder on the 3-TDV very accurate positioning is achieved. The diverters are designed to be easily removed from the line for cleaning (COP – cleaning out of place). It is also possible to purge the individual conveying lines with a cleaning liquid without removing the diverter from the line (CIP – cleaning in place). Removal from the line is only necessary when a complete cleaning operation is required. This gives the customer the option to chose a cleaning method tailored to suit their process. The 2/3-TDV and M-TDV tube diverter range includes USDA Dairy Accepted models.

The M-TDV transports pneumatically conveyed products in powder or pellet form to or from multiple destinations (diverging or converging). The M-TDV design is simplicity itself, and guarantees a high positional accuracy with a minimum of component parts. Available in sizes from 40 to 150 mm (1½" to 6"), with up to 14 ports on the larger models i.e. smaller pipe sizes. The normal supply would consist of the diverter unit, a pre-programmed compact controller with an onboard PLC. The controller works with a binary code input from the customer’s PLC. The M-TDV range includes USDA Dairy Accepted models.

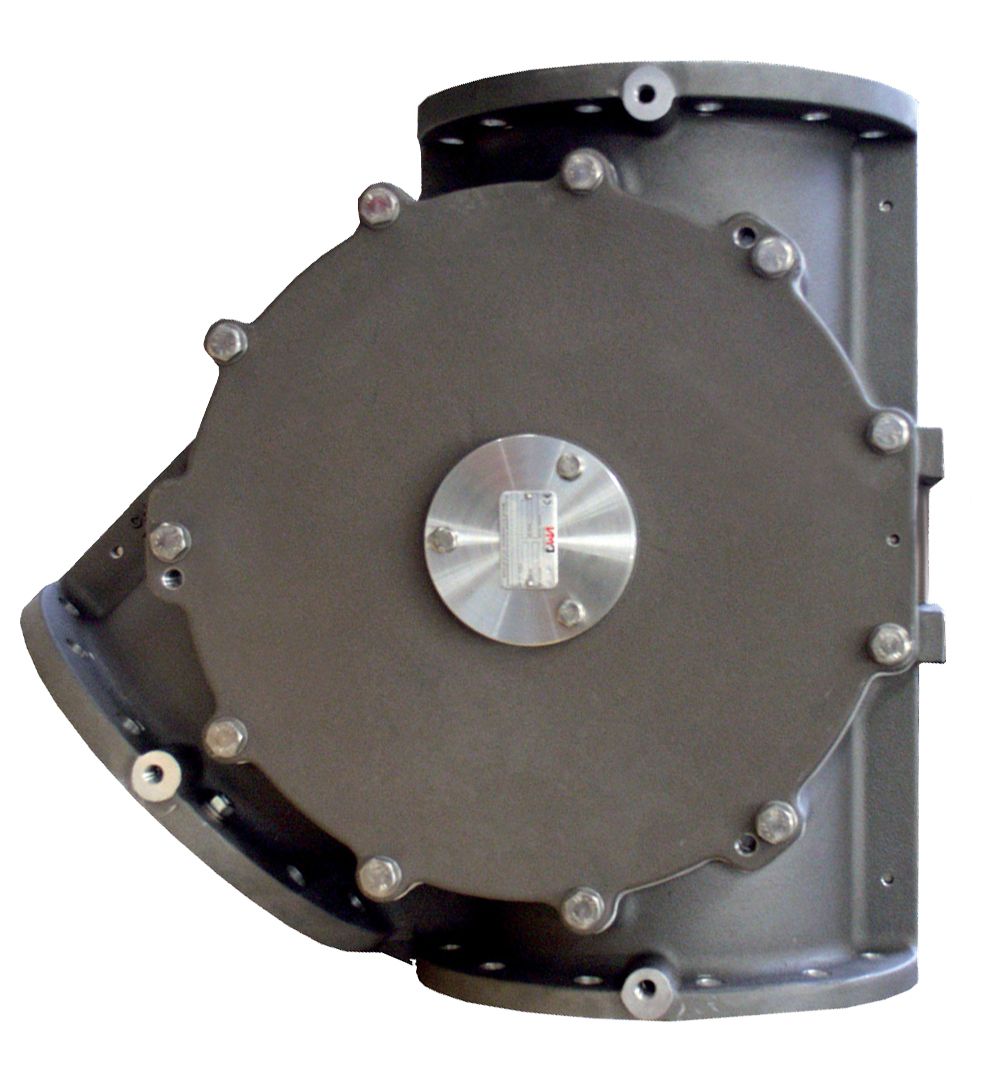

The BTD ball type diverter has been specifically designed to converge or diverge abrasive products in pneumatic conveying systems. The diverter is also suitable for systems having relatively high pressures and temperatures, e.g. thermoelectric power stations (coal and fuel oil ash), incinerators, foundries and cement, glass, ceramic, limestone, gypsum and chemical factories. The diverter can be used for both diverting and converging. When diverting the product itself provides the wear surface (most common application). When converging the impact area of the product on the diverter has been considerably strengthened (see dimensional drawing). The BTD is made from ductile spheroidal cast iron and is available in 7 sizes in the ranges 65 - 250.